Acoustic Emission System

Acoustic Emission System is powerful evaluation system that can be deployed within a wide range of applications of non-destructive testing using Acoustic Emission sensor. The source of these emissions in material is closely associated with deformation, crack, leakage in a structure under stress. AE System we can detect of estimate a material and damage condition of structure.

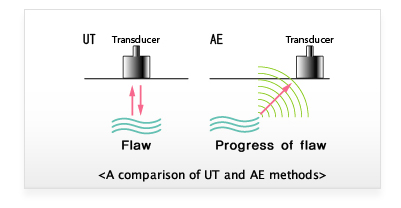

Characteristic of AE

Acoustic Emission Testing is similar to UT (Ultrasonic Testing) with wideband frequency range from 10kHz to 1.2 MHz, but can detect the dynamic energy associated with the degradation of structural integrity. Following is advantage of AET.

- · Early and rapid detection of defects, flaws, cracks etc.

- · Real time monitoring

- · Defective area location: only critical defects provide sustainable Acoustic Emission sources.

- · Minimization of plant downtime for inspection, no need for scanning the whole structural surface.

- · Source location the related to defect of structure is available using multi AE sensors.

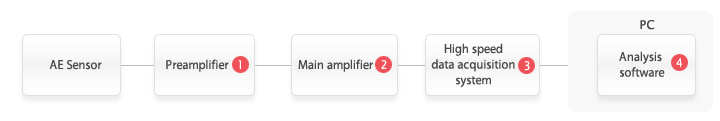

AE System Configuration

Generalized AE System configuration is as follows.

| 1 Preamplifier | The preamplifier provides filtering, gain (uV to mV) and cable drive capability |

| 2 Main amplifier | The main amplifier provides 2nd filtering, gain, RMS/Raw data out, and supply a power for sensor. |

| 3 High speed data acquisition system | To measure with AE frequency range from 20kHz to 1.2MHz, AE system is required high speed signal processing |

| 4 Analysis software | The Analysis software provides crack and leakage condition from AE features, Additionally, it provides source location as an optional |

※ Customized system is also available for the special purpose.